Our Core Values

SAFETY

We believe that a safe work environment is crucial to maintaining any successful business.

Employees are our greatest asset and we guarantee that they are provided with the safest possible work environment.

QUALITY

We are committed to providing our customers with the

highest quality product.

We understand that our customers expect nothing less

than conforming hardware.

SCHEDULE

We know that on-time delivery is critical. Our customers rely on Mega Precision to deliver

products to their production line on time.

We ensure that needs are met through open communication

and transparent operation.

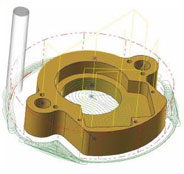

We Specialize in the following

- Milling and turning of precision components for the commercial, military, and aerospace industries

- Machining steel, stainless steels, aluminum, nickel, Inconel, plastic, and titanium

- High-quality tight tolerances

- Quality and on-time delivery

- Great relationships with our customers and our employees

Capabilities

- 12″ Turning diameter

- Fully equipped deburring area

- SolidWorks

- Mastercam

Turning (5) – Two Inch Bore

- Four 8″ Chuck CNC Turning Centers – 3 Okumas & 1 Haas ST 20

- One 10″ Chuck Okuma CNC Lathe

Milling (7) – Equipped with

Renishaw Probes

- 5 Axis Haas UMC 750 with 30″ x 20″ x 20″ travel – Through Spindle Coolant

- 5 Axis Haas VF-4 with 50″ x 20″ x 25″ travel

- 4 Axis Haas VF-3 with 40″ x 20″ x 25″ travel – Through Spindle Coolant

- 4 Axis Haas VF-3SS with 40″ x 20″ x 25″ travel – Through Spindle Coolant

- 3 Axis Haas Super Mini Mill 2 with 20″ x 16″ x 14″ travel

- 3 Axis Okuma M5660-V with 41.34″ x 22.05″ x 18.11″ travel – Through Spindle Coolant

- 4 Axis Matsuura RA-3G II with 31.5″ x 20.1″ x 9.7″ travel – Pallet Changer – Through Spindle Coolant

Main Inspection Equipment

We are committed to providing our customers with the highest quality product. We understand that our customers expect nothing less than conforming hardware.

- Wenzel X–Cite 55,600CMM

- Brown and Sharpe Micro – Hite 350

- MicroVu Spectra optical comparator